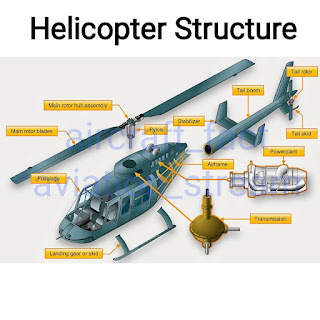

Helicopter Structure

🛩️The major components of a helicopter are the airframe, fuselage, landing gear, powerplant/ transmission, main rotor system, and antitorque system.🛩️The airframe, or fundamental structure, of a helicopter can be made of either metal or wood composite materials, or some combination of the two. Typically, a composite component consists of many layers of fiber- impregnated resins, bonded to form a smooth panel. Tubular and sheet metal substructures are.

🛩️The major components of a helicopter are the airframe, fuselage, landing gear, powerplant/ transmission, main rotor system, and antitorque system.

🛩️The airframe, or fundamental structure, of a helicopter can be made of either metal or wood composite materials, or some combination of the two. Typically, a composite component consists of many layers of fiber- impregnated resins, bonded to form a smooth panel. Tubular and sheet metal substructures are usually made of aluminum, though stainless steel or titanium are sometimes used in areas subject to higher stress or heat. Airframe design encompasses engineering, aerodynamics, materials technology, and manufacturing methods to achieve favorable balances of performance, reliability, and cost.

🛩️A simplified explanation of how a helicopter flies is that the rotors are rotating airfoils that provide lift similar to the way wings provide lift on a fixed-wing aircraft. Air flows faster over the curved upper surface of the rotors, causing a negative pressure and thus, lifting the aircraft. Changing the angle of attack of the rotating blades increases or decreases lift, respectively raising or lowering the helicopter. Tilting the rotor plane of rotation causes the aircraft to move horizontally usually made of aluminum, though stainless steel or titanium are sometimes used in areas subject to higher stress or heat. Airframe design encompasses engineering, aerodynamics, materials technology, and manufacturing methods to achieve favorable balances of performance, reliability, and cost.

🛩️A simplified explanation of how a helicopter flies is that the rotors are rotating airfoils that provide lift similar to the way wings provide lift on a fixed-wing aircraft. Air flows faster over the curved upper surface of the rotors, causing a negative pressure and thus, lifting the aircraft. Changing the angle of attack of the rotating blades increases or decreases lift, respectively raising or lowering the helicopter. Tilting the rotor plane of rotation causes the aircraft to move horizontally.

➡️Subscribe us for more aircraft knowledge and aircraft fact⬅️

➡️Do Share with your Friends⬅️

Comments

Post a Comment